MES (Manufacturing Execution System) is a real-time information management system used in manufacturing workshops and factories to monitor and coordinate production processes, ensuring efficient production, high-quality products, traceability, and safety. MES systems are crucial in modern manufacturing, helping companies improve production efficiency, reduce costs, and enhance quality.

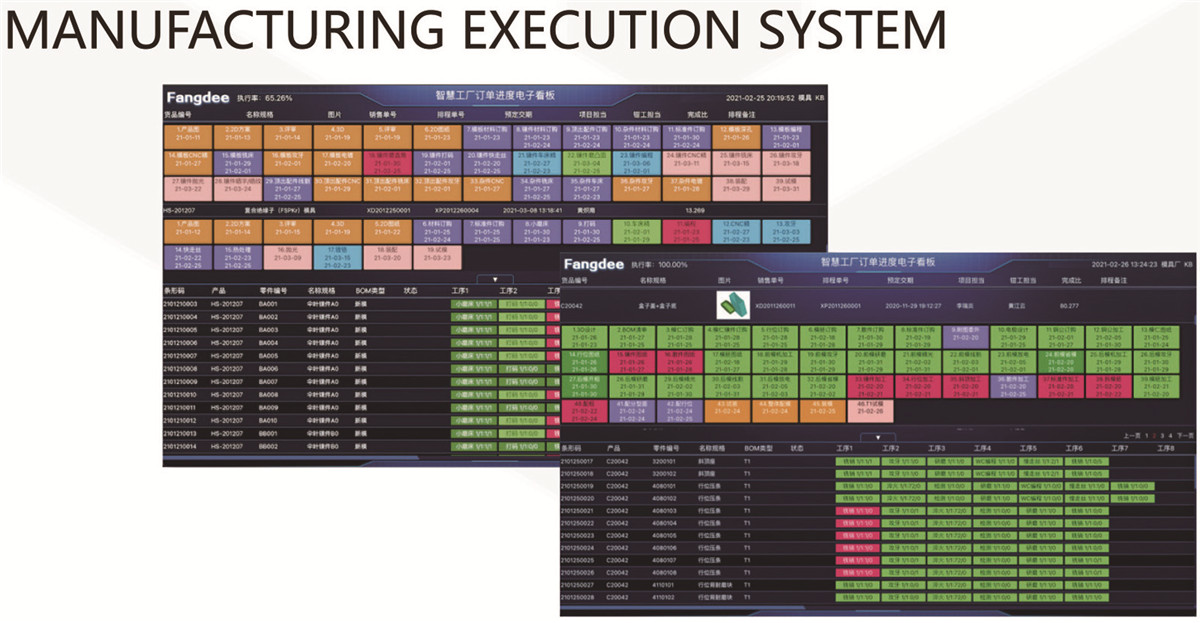

To further enhance factory production efficiency and management, Zhuohang Precision has implemented the most advanced MES system in the industry. This system also integrates ERP functionality, allowing for data sharing and synchronization within the company, fostering collaboration among departments, and enabling comprehensive information management.

The primary functions of the MES system include:

1. Manufacturing Planning and Scheduling: The MES system automatically generates production plans and schedules based on order demands and material inventory. It optimizes and adjusts plans to match current factory conditions and equipment capabilities, ensuring smooth production processes.

2. Manufacturing Execution: MES monitors and tracks the entire production process, from raw material input to equipment status, product processing, and final product quality testing. This ensures that each step of production follows the predetermined plan.

3. Equipment Management: MES oversees production equipment, including status monitoring, fault diagnosis, maintenance, and servicing, to ensure stable and reliable operations.

4. Traceability Management: MES records data and product information for each production stage, such as raw material sources, usage, process parameters, equipment data, production batches, processing times, operators, and quality inspection results. This promotes product traceability and reduces quality issues and recall risks.

5. Data Analysis: MES collects various data during production, such as equipment utilization and production efficiency, and performs analysis and optimization. This helps companies continuously improve production processes, increase efficiency, and enhance product quality.